WHAT IF THERE WAS A DEPENDABLE WAY TO ENSURE THE SAFETY & SECURITY OF YOUR MOST CRITICAL BOLTED JOINTS?

WITH SMARTBOLTS®, THERE IS. WE GUARANTEE IT.

THE APPRECIATION OUR OPERATORS HAVE EXPRESSED IS PRICELESS.”

WE’RE SAVING TENS OF THOUSANDS IN OVERTIME AND DOWNTIME AND OUR WORKERS ARE HAPPY.”

TECHNOLOGICAL INNOVATION

FITS YOUR PROCESS

BUILT TO LAST

- Minimize unplanned maintenance

- Reduce operating costs

- Improve overall productivity

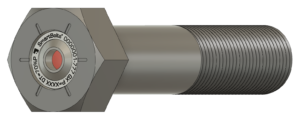

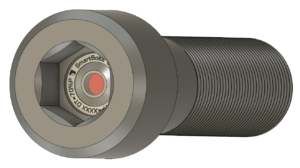

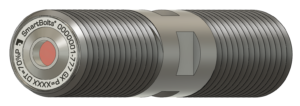

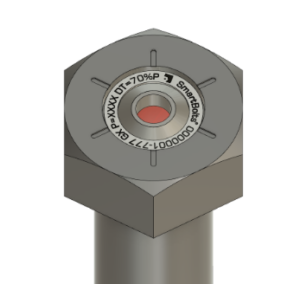

Measure What Matters

Establishing and maintaining a specific amount of clamp force is the primary goal of bolting. Clamp force is what keeps a bolted connection tight and secure. As a SmartBolt DTI is tightened, tension forces it to stretch, and the visual indicator changes color to represent the amount of tension in real-time. “Torque” is simply a measurement of the twisting force required to spin the nut up along the threads of a bolt, whereas “Tension” is the stretch or elongation of a bolt that provides the clamping force of a joint.

Using no batteries or moving parts, SmartBolts’ built-in, color-coded visual tension indicator will continuously monitor the bolt’s tension to ensure the safest, most reliable connection possible.