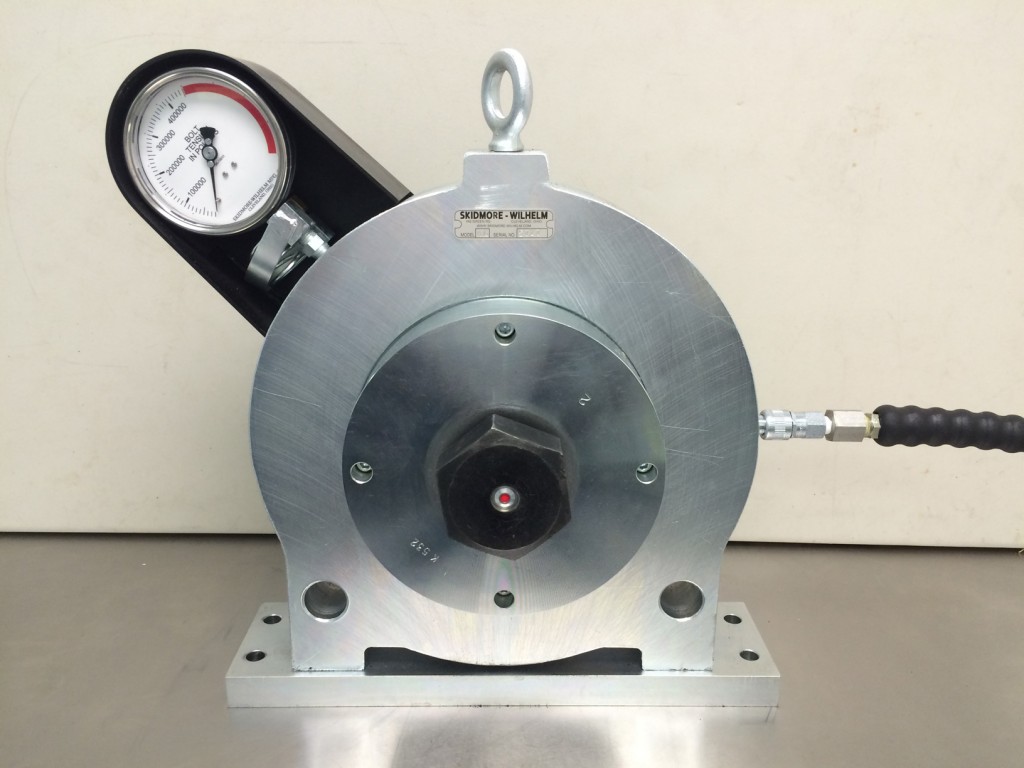

Stress Indicators, Inc. has expanded its manufacturing range to satisfy customer demand for SmartBolts® in applications that require large diameter fasteners. SmartBolts in diameters as large as 2-1/2” (M64) can now be tested in our new Skidmore-Wilhelm Model K tension tester. The Model K is the largest unit available from the company, and it was developed to meet the needs of the wind turbine industry.

Stress Indicators uses this hydraulic tension calibrator to perform accuracy and quality control tests on SmartBolts from 1-1/4” (M32) to 2-1/2” (M64) in diameter, at tensile forces up to 450,000 lbs. The Model K can test a wide variety of bolts, cap screws, and studs.

Our testing procedures ensure that 100% of SmartBolts conform to demanding quality control standards, regardless of size or shape. Every SmartBolt is tested under tension until the color of the indicator, as measured by a monochromatic reflectometer, reaches a prescribed value. A summary of the results of these tests are supplied to our customers in a Certificate of Compliance document. Full documentation of test results is available upon request.

Stress Indicators, Inc. is constantly working to provide a wider variety of product choices to our customers while retaining the strict quality control methods that our customers expect. Product quality is our most valuable asset and we are proud to continue this tradition with a growing range of available SmartBolts.