We recently manufactured the largest DTI SmartBolts® to date at the request of mining equipment manufacturer FLSmidth. Weighing in at over 10 lbs., these SmartBolts are 2” in diameter and include our two most popular product upgrades: a Protective Recess and a Contamination Seal. The Protective Recess reduces the risk of impacts to a SmartBolt indicator and is recommended for fasteners with diameters of 7/8” (M22) and greater, while the Contamination Seal adds a clear epoxy surface over the indicator which protects the mechanism from liquids and other contaminants.

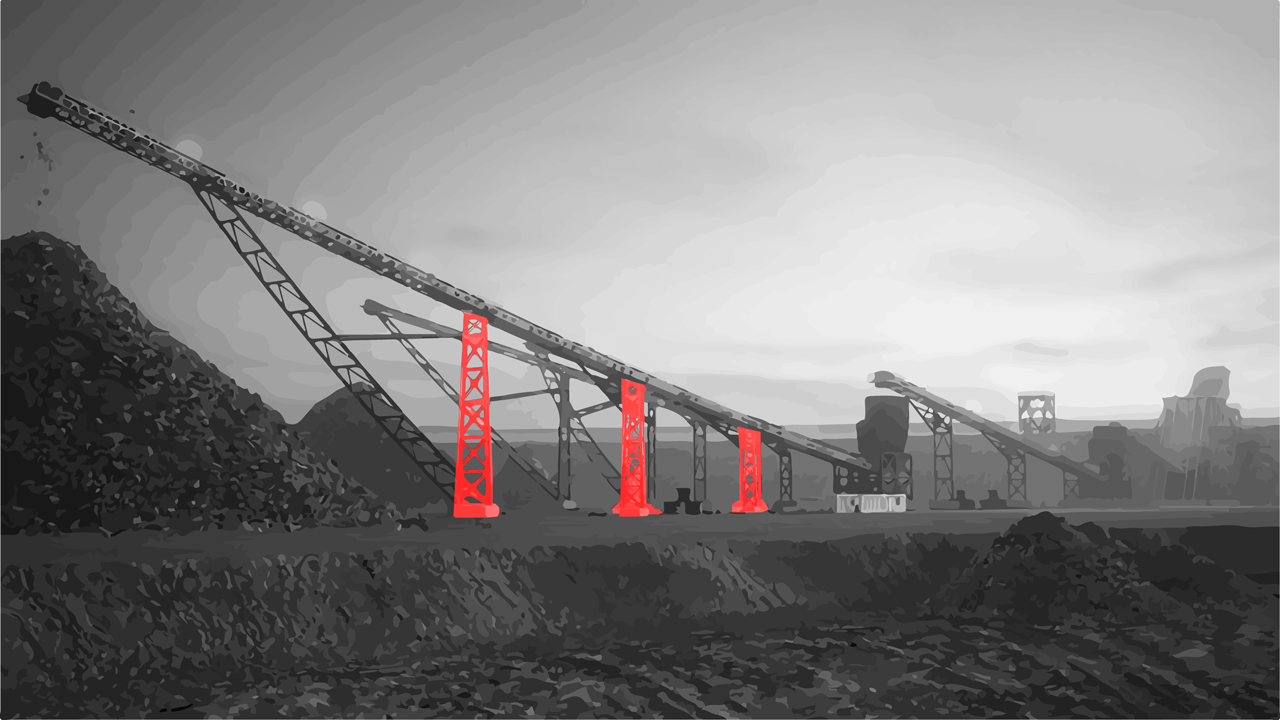

These 2” SmartBolts are designed for use in mobile stacking conveyors for the Chilean mining industry. The product upgrades ensure that these fasteners will perform as expected in extreme and rugged environments where operational uptime is of paramount importance. SmartBolts are relied upon to provide accurate bolt tension indication in a wide range of environments around the world.

For this application, FLSmidth has specified the SmartBolts® Visual Indication System™ to confirm that critical fasteners are properly tensioned with 130,000 lbs. of force. An indicator, clearly visible on the fastener head, provides visual verification of tension with changes of color according to bolt tensile load. Mobile stacking conveyors transport large volumes of raw materials to be piled, or “stacked,” on to a stockpile for future reclamation. A single conveyor is supported on a series of truss frames, each connected by a specially developed joint that allows the machine to follow uneven ground conditions and relieve stresses that could damage the structure. Failures within these joints can result in substantial and expensive operational delays. SmartBolts, installed in these joints, provide visual feedback that the critical bolts are properly tensioned and the conveyor is safe to operate.

In addition to improvements in safety and uptime, SmartBolts provides the Chilean mine operator with reduced installation and maintenance costs. Rather than relying on inaccurate torque tools, this mining company can inspect critical bolted joints for proper clamp force with an efficient visual confirmation of tension, reducing the time and effort required to complete these routine activities.

Learn how visual indication of fastener tension is transforming industries around the world – contact us for an information package.