Powering the TEREX RH340 Hydraulic Excavator

| World Records: Largest DTI SmartBolts | ||

|---|---|---|

| Date | Diameter | Application |

| 2013 | 1.5″ | Phosphate Mine Slurry Pump |

| 2014 | 2″ | Mobile Stacking Conveyor |

| 2017 | M56 (2.2″) | Slewing Ring Bearing |

| 2021 | M65 (2.5″) | Counterweight Bolts |

In the world of heavy machinery, every component plays a vital role. Meet the M64 hex head cap screws, the world’s largest SmartBolts, securing the counterweight of the TEREX RH340 Hydraulic Excavator.

| Key Details | |

|---|---|

| Equipment | TEREX RH340 Hydraulic Excavator (600 tons) |

| Application | Counterweight Bolts |

| Bolt Specifications | M64 x 640mm |

| Bolt Diameter | M64 (2.5”) |

| Date | January 2021 |

Unmatched Strength

These M64 hex head cap screws are not your average bolts. Designed for unparalleled strength, they can handle a tension of 1660 kN, equivalent to over 370,000 pounds. Installed in January 2021, they fortify the TEREX RH340, ensuring stability during the most demanding tasks.

Innovation in Action

As SmartBolts, these components go beyond conventional fasteners. They represent a fusion of precision engineering and innovation, setting new standards for safety and reliability in the heavy machinery industry.

In a world of giants, SmartBolts like these are the unsung heroes, quietly but robustly ensuring the reliability and safety of colossal machines like the TEREX RH340 Hydraulic Excavator.

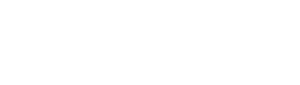

2017’s Largest SmartBolt!

We’ve broken another record! The world’s largest DTI SmartBolts have been recently manufactured.

| World Records: Largest SmartBolts | ||

|---|---|---|

| Date | Diameter | Application |

| 2013 | 1.5″ | Phosphate Mine Slurry Pump |

| 2014 | 2″ | Mobile Stacking Conveyor |

| 2017 | M56 (2.2″) | Slewing Ring Bearing |

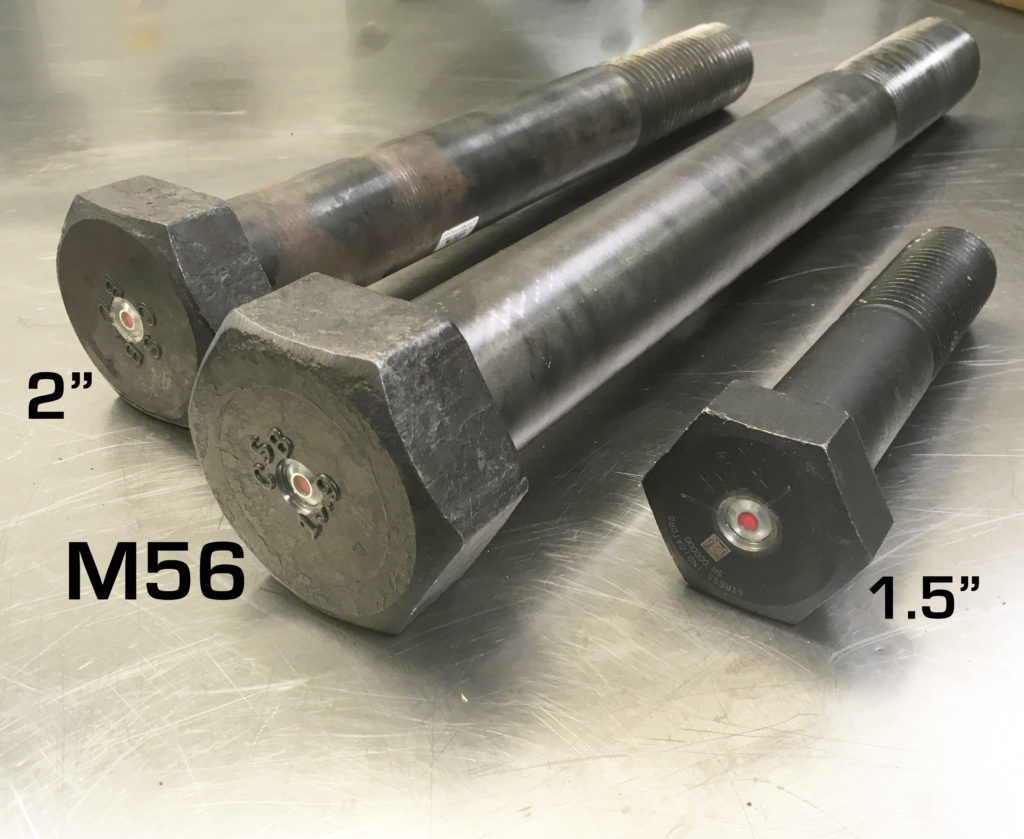

M56 hex head cap screws that will be used to bolt giant slewing ring bearings in mining excavators. A slewing ring bearing is an oscillating or rotating bearing, often mounted horizontally, that supports a heavy but slow-turning load, such as a crane or excavator.

As seen in these photos, the previous record holders are no comparison for the new champion! The new World’s Largest record holder weighs more than 25 lbs., and is over 500mm (20″) long and 56mm (2.2″) in diameter. With a Design Tension of nearly 300,000 lbs., these bolts are ready to secure these critical slewing ring bearings! They include our two most popular product upgrades: a Protective Recess and a Contamination Seal. The Protective Recess reduces the risk of impacts to a SmartBolt indicator, while the Contamination Seal adds a clear epoxy surface over the indicator for additional durability.

A mining services company that performs bearing replacements offers these SmartBolts to guarantee the bearings they install are properly preloaded, and to ensure ease of maintenance and long service life to their customers. The visual indicator in SmartBolts allows installers to verify that the critical bearing bolts are properly tensioned, and allows inspectors to use a quick visual check to see that residual bolt tension is still present during service.

More and more users of heavy equipment that rely on slewing bearings are upgrading their bearing bolts to SmartBolts. The entire structure depends on these bolts being properly preloaded for safety and operational integrity, and SmartBolts offer a cost-effective visual means to ensure proper tension, especially after months of service. In addition, there can be inherent challenges of achieving a proper and consistent preload with large diameter bolted joints. Read about our project to install SmartBolts in slewing bearings of a shiploader manufactured by Agrico Sales.

Do you have an application that can benefit from SmartBolts? Learn how visual indication of fastener tension is transforming industries around the world – contact us for an information package.

Innovation in Action